Navigator >>> ferforjemakineleri >>> Forging Hammer Machine

Forging Hammer Machine (HAMMER60)

hammer/AdvancedHammerCraft.

hammer/EfficientForgeMaster.

hammer/EfficientHammerTech.

hammer/ForgeMachineryShowcase.

hammer/ForgeMaster_ProductShot.

hammer/HighPowerHammerTech.

hammer/ModernForgeSetup.

hammer/advanced_forging_unit.

hammer/advanced_hammering_device.

hammer/advanced_hammering_unit harness testing.

hammer/automated_forging_hammer_system exportation.

hammer/custom_forging_machine.

hammer/cutting-edge_forging_technology.

hammer/efficient_forging_hammer.

hammer/efficient_forging_solution.

hammer/efficient_hammering_technology.

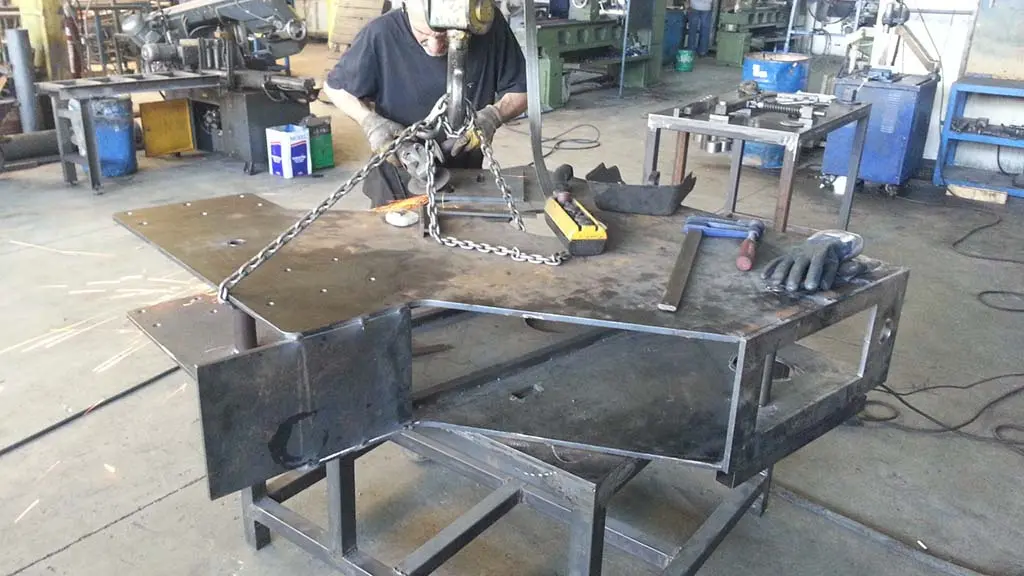

hammer/forging_hammer_assembly.

hammer/heavy-duty_forging_machine production.

hammer/heavy_industrial_forging.

hammer/high_power_hammer_machine.

hammer/industrial_forging_hammer.

hammer/industrial_hammering_technology.

hammer/machinery_for_forging.

hammer/modern_forging_hammer_setup.

hammer/modern_forging_machine.

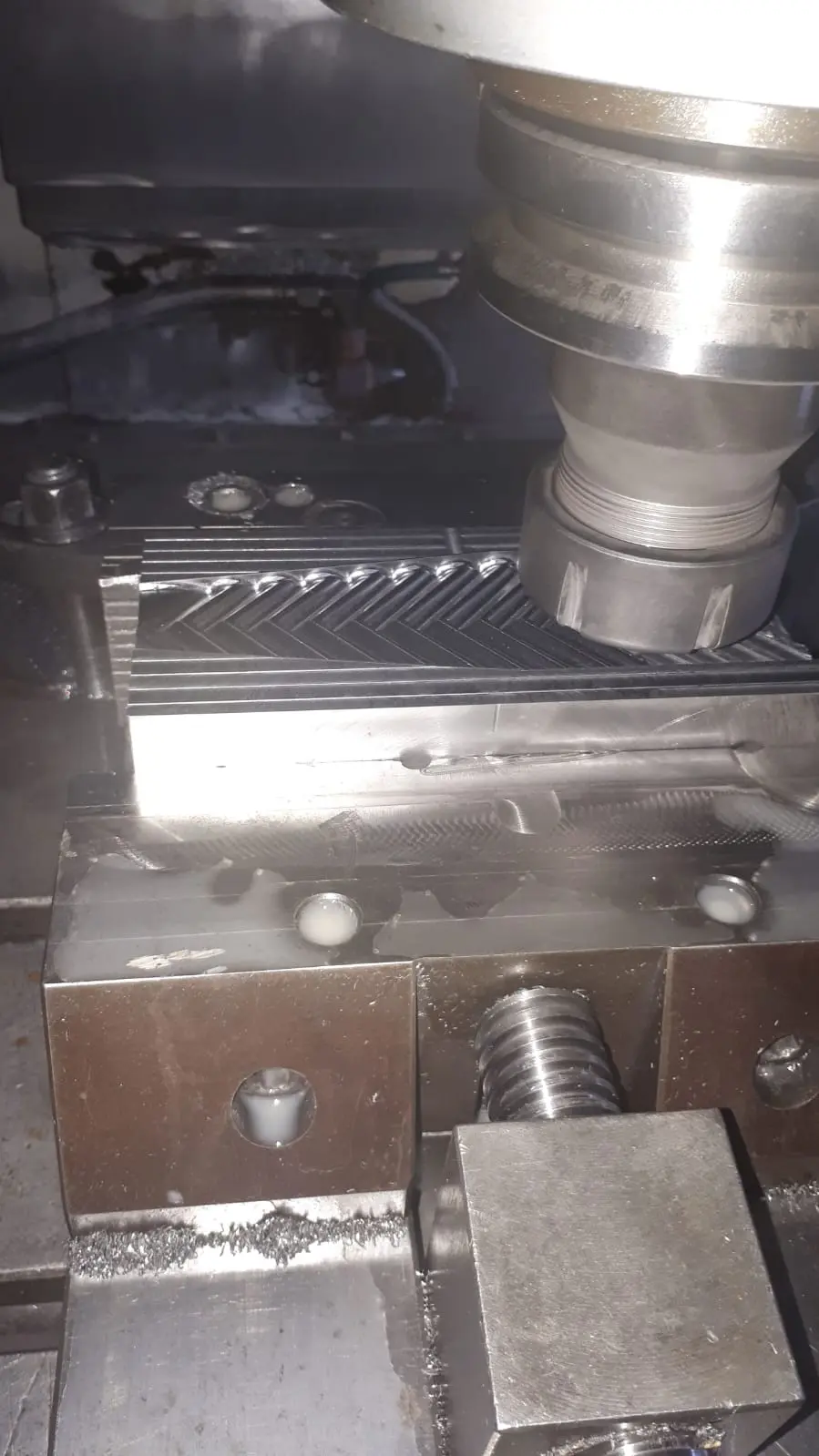

hammer/molds for specialized_forging_system.

hammer/powerful_forging_hammer.

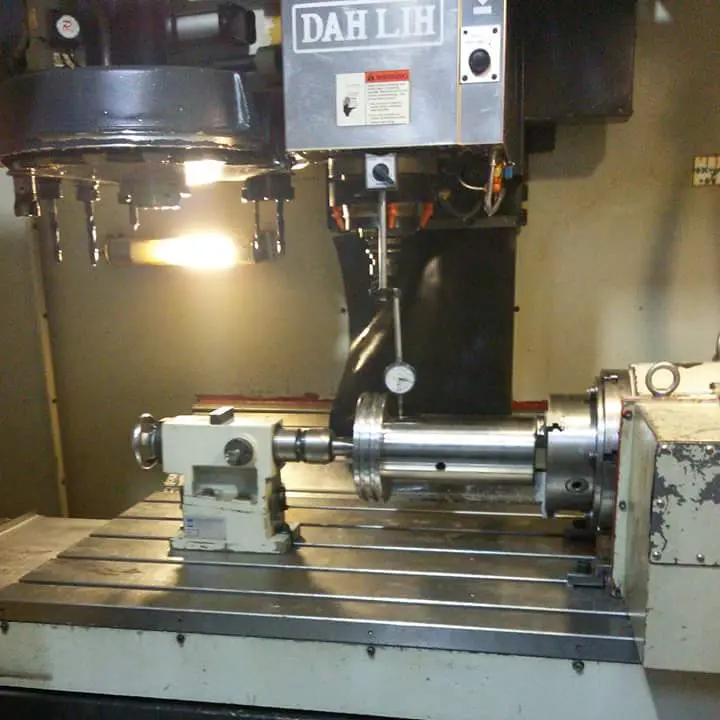

hammer/precision_forging_tool on cnc.

hammer/precision_hammering_machine.

hammer/specialized_hammering_system.

The Power Hammer Machine Introduction

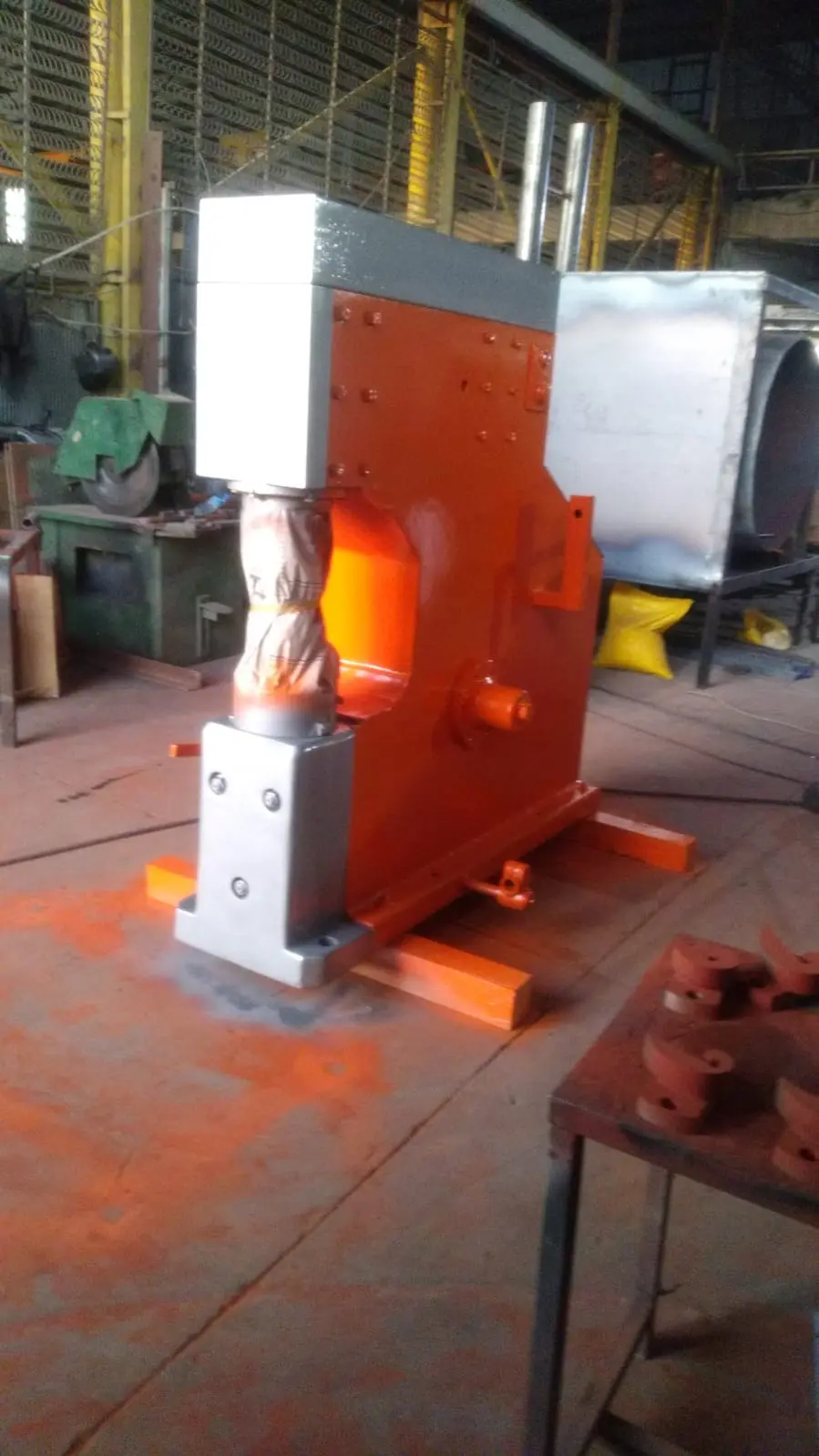

The Power Hammer Machine, also known simply as a Power Hammer, has been my favorite machine to work with thus far. What makes it special? It's akin to crafting a car engine. Every step, from production and casting to selecting materials, designing molds, shaping pistons, honing, rectifying, and applying seals and heat treatments, contributes to its unique charm. The culmination of these processes results in a resounding, locomotive-like sound that's truly delightful.

History

This ingenious machine traces its origins back to the 1850s, credited to a German inventor. Its design is a testament to meticulous study, drawing from the best power hammers globally while infusing innovative ideas. The result? A faster, more powerful, and efficient power hammer.

Special Contributions

I extend special gratitude to Ömer Gülüşen for his invaluable contributions to refining the casting molds and piston system of our Power Hammer. For instance, our model's hammer weight isn't just 60 kg; it's been optimized to 62 kg, doubling efficiency with just 2 strokes instead of 4.

Features

Our Power Hammer stands out with its superior features and versatility as a forging press. It garnered initial recognition from Romania, thanks to Mehmet Çetinkaya's efforts in connecting our product with foreign markets, supported by our adept Sales Director.

Transformation

The machine's adaptability shines through when molds are switched, seemingly transforming its functionality. Its pneumatic prowess makes it a must-have in any workshop.

Our Business

Greetings to our esteemed friends and valued customers! Let me shed light on our latest endeavor at Cengizler Kalıp Makine. To those wondering why choose our machine, allow me to explain. Over our 15-year journey, we've amalgamated various forging processes such as edge shaping and tapping into a single, groundbreaking solution. This milestone, dating back scientifically to the 1880s and pioneered by a German inventor, represents our dedication to innovation.

While Turkey's industrial landscape may have lacked foreign influence, our quest for excellence remained undeterred. With inspiration from our late founder, Ahmet Faruk Cengiz, and Ferit Celal Cengiz, we embarked on a year-long journey to amalgamate the best features of three renowned brands into one ergonomic, robust machine. The result? Enhanced striking power, faster response times, and years of reliable operation.

Heartfelt thanks to all who've embraced and tested our creation. I extend my utmost respect and appreciation to our customers across Spain, Romania, Azerbaijan, Russia, Lebanon, Yemen, Morocco, Tunisia, Algeria, Canada, the UK, USA, and Bulgaria.

Forging Furnace

A forging furnace is a fundamental component in the metalworking process, essential for heating metal to a malleable temperature suitable for shaping. Operating at high temperatures, it creates an environment where metal molecules relax, allowing for precise forging without compromising structural integrity. From intricate ornamental designs to industrial-grade components, the forging furnace plays a pivotal role in shaping raw metal into finished products of exceptional quality and durability.

Power Hammer

Power hammers deliver controlled strikes to metal surfaces, shaping them according to desired designs.

Forge

A forge serves as the heart of any metalworking operation, providing the heat necessary to shape raw metal into a desired form. With a wide range of options available, including gas forges and induction forges, metalworkers can choose the type that best suits their specific needs and preferences. Whether crafting intricate designs or industrial-grade components, the forge remains an indispensable tool for heating and shaping metal with precision and efficiency.

Blacksmith Tools

Essential tools for metalworking, including power hammers and forging presses, ensure precision and quality craftsmanship.

Ornamental Ironwork

Ornamental ironwork is a specialized craft that demands the use of high-quality wrought iron to create visually striking fences, gates, and decorative elements. The intricate designs and delicate details characteristic of ornamental ironwork require materials that offer both durability and aesthetic appeal. Wrought iron, known for its strength and malleability, serves as the foundation for these artistic creations, allowing skilled artisans to fashion elaborate designs that enhance architectural beauty and add a touch of elegance to any space. Whether adorning a historic building or accentuating a modern landscape, ornamental ironwork showcases the timeless beauty of wrought iron craftsmanship.

Pneumatic Hammer Machines

Investing in pneumatic hammer machines, whether new or second-hand, can significantly enhance metalworking efficiency.

Air Hammers: Essential Tools for Various Applications

Air hammers, also known as pneumatic hammers or air-powered hammers, are versatile tools widely used in construction, automotive, manufacturing, and metalworking industries. These tools utilize compressed air to deliver powerful blows, making them ideal for tasks that require forceful impact.

Here are some common types and uses of air hammers:

- Air hammer hammer: These hammers feature a pneumatic mechanism that allows for precise control and efficient operation. They are commonly used in metalworking and fabrication for shaping and forming metal.

- Pneumatic hammer: Similar to air hammers, pneumatic hammers are powered by compressed air and are used for various tasks such as chiseling, cutting, and riveting.

- Air hammer bits: These are the interchangeable tips or attachments used with air hammers for different applications. Common types of air hammer bits include chisels, punches, and cutters.

- Electric air hammer: While traditional air hammers are powered by compressed air, electric air hammers utilize electricity for operation. They are often preferred for indoor or stationary applications where air compressors may not be available.

- Air hammer chisel: Chisels are one of the most commonly used attachments for air hammers. They are designed for cutting, carving, and shaping various materials such as metal, wood, and stone.

- Pneumatic jack hammer: These heavy-duty air hammers are designed for demolition and breaking tasks. They are commonly used in construction and roadwork for breaking up concrete, asphalt, and other hard materials.

- Air hammer harbor freight: Harbor Freight is a popular retailer known for offering a wide range of tools and equipment, including air hammers. Air hammers purchased from Harbor Freight are often affordable and suitable for DIY or light-duty applications.

- Heavy duty air hammer: Heavy-duty air hammers are designed for demanding applications that require high impact force and durability. They are commonly used in industrial settings for tasks such as forging, metal shaping, and heavy-duty fabrication.

Whether you need to chisel, cut, shape, or demolish, air hammers offer the power and versatility to get the job done efficiently. With a wide range of attachments and capabilities, these tools are essential for any professional tradesperson or DIY enthusiast.

For quality air hammers and accessories, be sure to explore reputable suppliers and manufacturers that offer reliable products tailored to your specific needs.

| HAMMER60 | |

| Operating System | Pneumatic |

| Normal Drop Weight | Actual 60 Kg |

| Number of Blows | 220 per minute |

| Maximum Stroke | 220 mm |

| Motor Power | 380 V 3 Phase - 7.5 kW |

| Motor Speed | 1450 times per minute |

| Die Area Dimensions | 150 x 78 mm |

| Total Weight | 1550 Kg |

| Forging Surface Weight | 355 Kg |

| Overall Dimensions | 741 mm x 1700 mm x 1640 mm |

| Warranty | Our product is under company warranty for 12 months from the date of delivery. Electrical components and the motor are not covered by the warranty. When necessary, Cengizler Machinery Company sends a technician to solve the problems. The customer is responsible for the technician's travel, accommodation, meals, daily allowance, and the transportation cost of the necessary spare parts. |

| Payment | %50 deposit, %50 before delivery |

| Delivery Conditions | Mersin Factory |

The 4 important advantages of the Power Hammer Machine:

60 kg Real Power

Friction and heat-resistant cast bearings.

Surface-hardened pistons.

Double ring slots on hammer

Why Should You Chose This Product?

Molybdenum alloy cast anvil.

The emergency button is available in our machine for emergency situations.

The design of Turkey's top three machines has come together in one machine.

We manufacture steel box for transportation, ensuring that your machinery remains undamaged during shipment.

The Most Popular Machine in Turkey. 4 Reasons

Educational and Consulting Services: We provide training and consultancy services to customers for the correct and effective use of our products.

We are proud: Our machines are operating in more than 50 countries.

Professional After-Sales Support and Service: We offer after-sales support and service to our customers.

The machine you purchase is covered by our companys warranty for 12 months.

Comments from Happy Customers :)

Bu makine verimliliği artırdı, teşekkür ederim! - Luka Novak, Slovenya

"감사합니다, 이 기계는 제 작업 흐름을 크게 개선했습니다!" - 박지윤

Top 100 Best Selling Machines Chosen by Customers

User-Friendly Design, Saving Time and Energy!

While our products provide high quality and reliability, we offer our customers economical solutions with competitive prices.

Hundreds of references worldwide. And happy customers :)

Affordable Spare Parts Service, Even if the Warranty Period Expires, We Still Support You!

"Order now to turn your dream wrought iron designs into reality and add a new dimension to your art!"